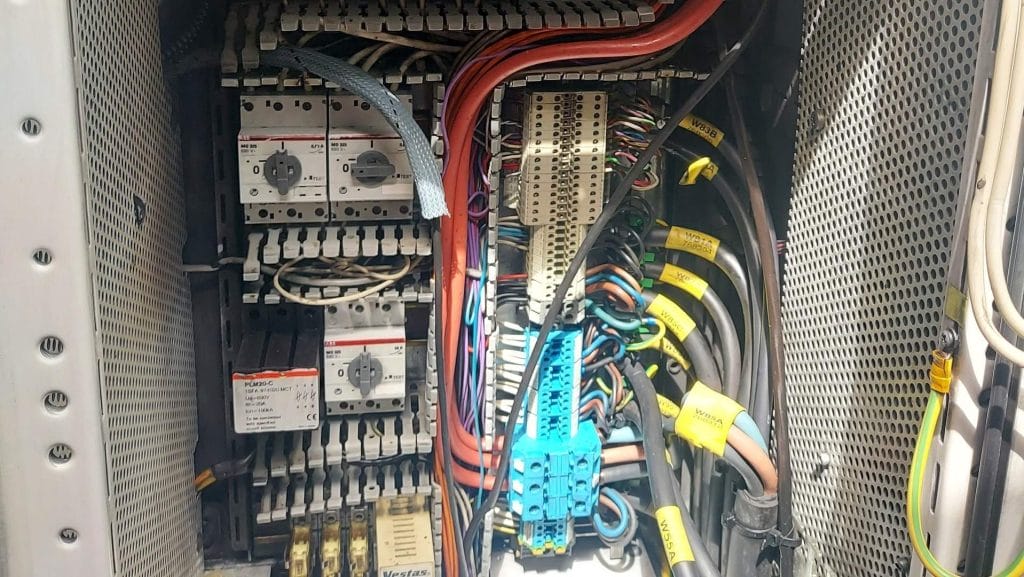

Fire Damage in the Converter Cabinet of a Wind Turbine

What happened?

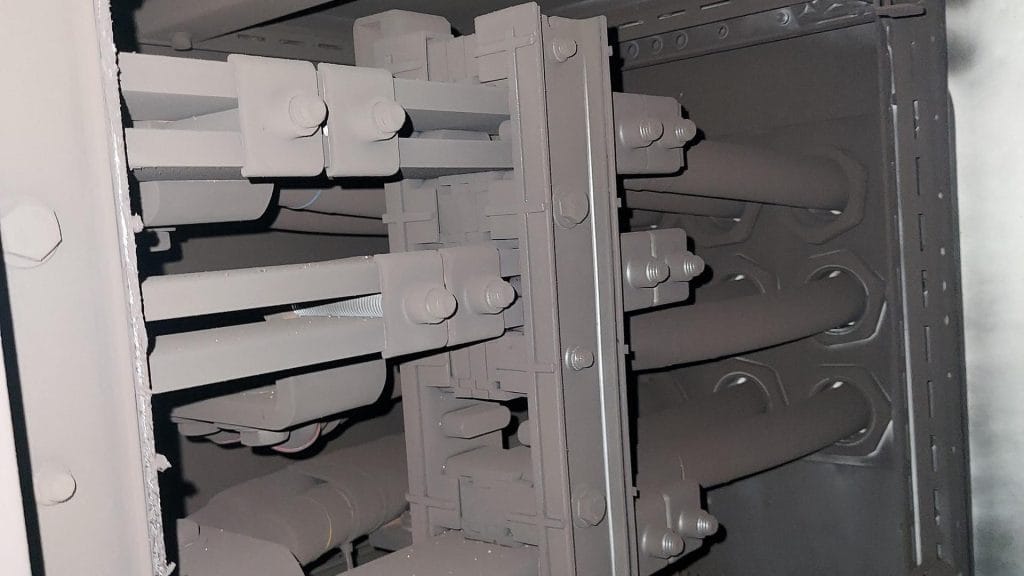

After a fire in the converter cabinet of a wind turbine, BELFOR was called in to determine the extent of the damage. The analysis revealed that the entire cabinet and its surroundings were heavily contaminated. Measurements showed a high chloride load.

The contamination posed significant risks to the system:

- Corrosion damage to bare metals, supports and bracing,

- Short-circuit danger for sensitive electrical components,

- Possible long-term consequential damage to operation and safety.

To avoid follow-up costs and prolonged downtime, fast professional remediation was necessary.

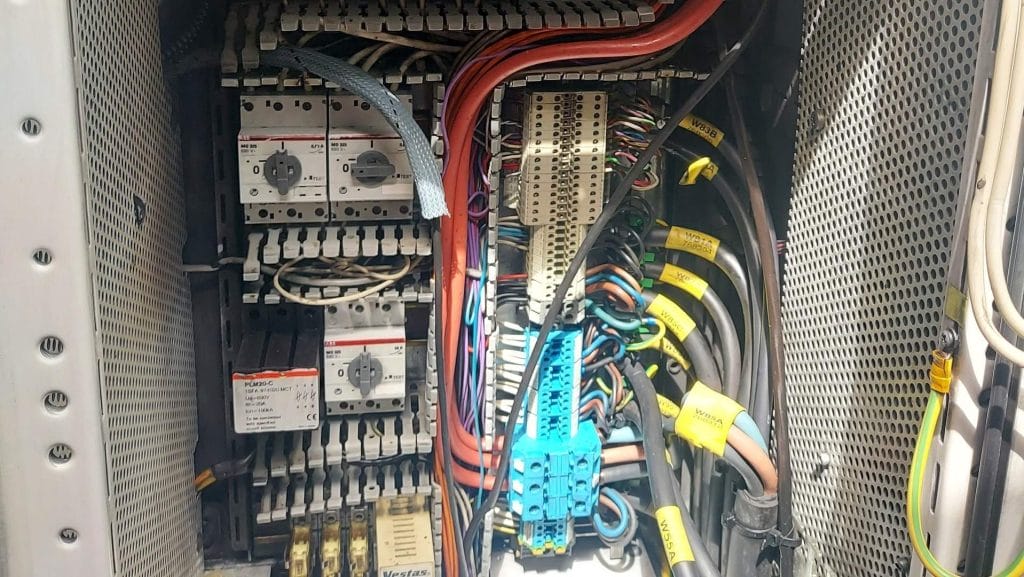

Before Restoration | After Restoration

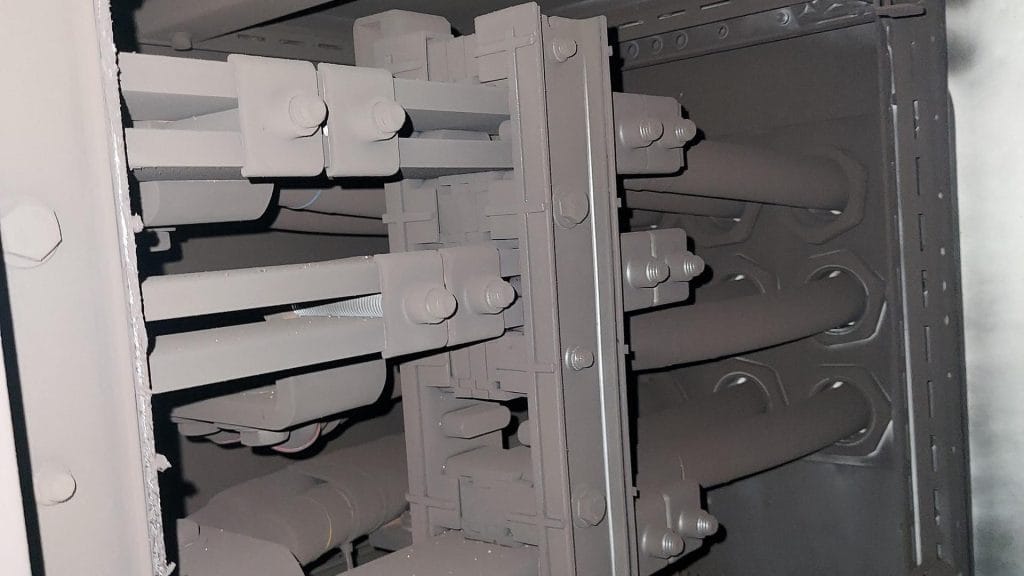

Remediation within two days

First, the affected converter cabinet and its surroundings were thoroughly cleaned of soot and foreign particles using high-performance vacuum cleaners and oil-free compressed air.

Next, technicians wiped all surfaces by hand with an alkaline BELFOR-cleaner, rinsed them thoroughly and dried them carefully.

Finally, the surfaces were neutralized so that no residue remained.

Quality control: Chloride tests confirmed that on the control cabinet, switch cabinet and generator no contamination was measurable after remediation.

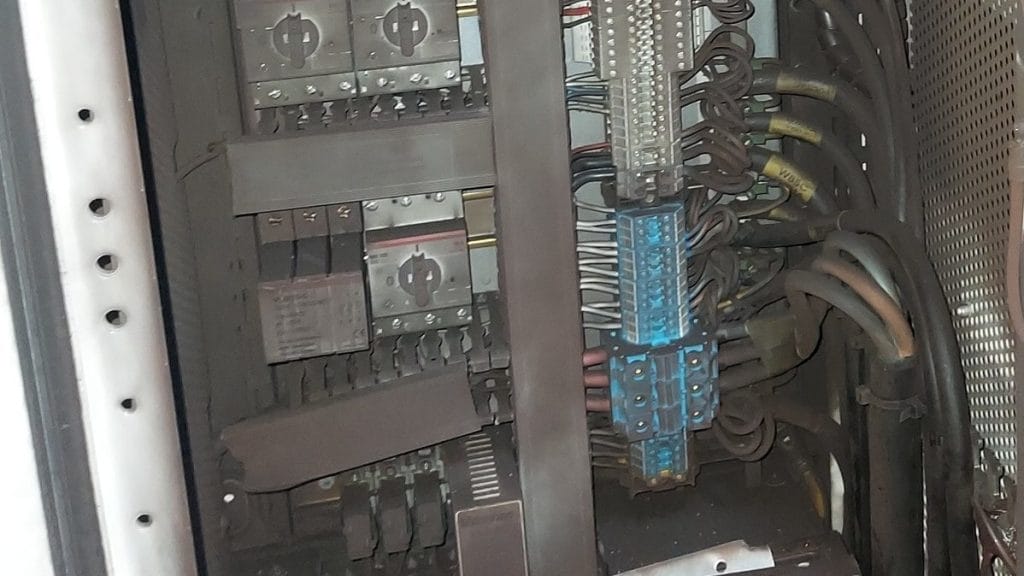

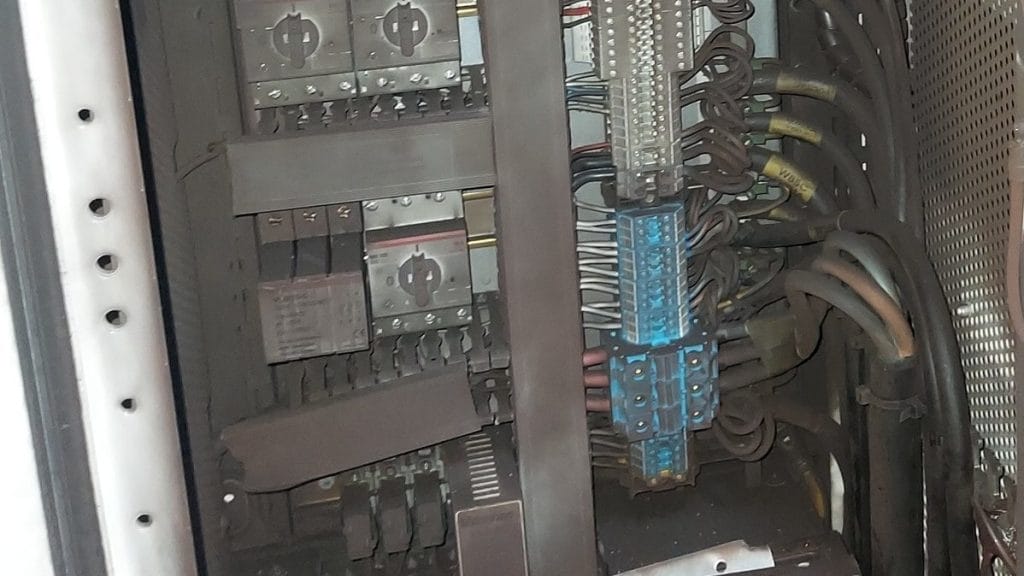

Before Restoration | After Restoration

Result

The restoration completely returned the plant to a safe condition: All measured chloride values on the treated surfaces were 0 µg/cm² upon completion of the work, meaning that neither corrosion nor short-circuit risks remained.

Thanks to the rapid implementation by BELFOR, downtime was reduced to a minimum and consequential damage was sustainably prevented.

The work was executed in accordance with DGUV Rule 101-004 (BGR 128) and the guidelines for handling hazardous substances. The wind turbine could be returned to operation without restrictions.

Before Restoration | After Restoration